2. The CEO has to get involved, which means he has to

neglect his actual strategic function.

3. Deadlines are repeatedly postponed.

4. The organizational size of the project is too large, so the team works inefficiently.

5. Customers need to be informed and are dissatisfied.

6. The costs are getting out of hand.

7. In the end, production quality problems occur.

8. Employees are dissatisfied and the search for a solution stalls.

Our goal at Reascentec is to live our brand essence by continuously going out of our comfort zone and focusing on the following goals: Providing assistance, streamlining and structuring the technical foundation, ensuring professional competence and success, delivering project metrics, establishing a lean and efficient organization and reducing costs.

b. Structuring and organizing of unstructured data

c. Creating logical product structures

d. Ensuring comprehensive documentation as the basis for optimization

e. Promoting networking within engineering

f. Ensuring compliance with relevant standards and regulations

the main challenge is often not their mere existence, but their consistent implementation

g. Know-How des vorhandenen Netzwerkes nutzen und Partner aktiv und frühzeitig in Produktentstehungsprozess einbinden

h. Introduction of company know-how as a manufacturer

i. Eigenverantwortung, Fehlertoleranz und Zuverlässigkeit

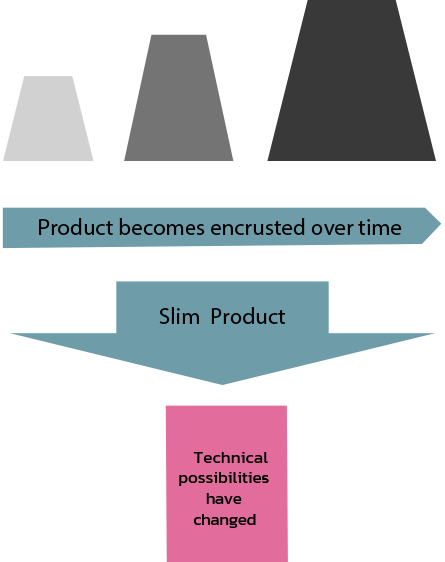

j. First streamline, then digitize

k. Gradual streamlining and structuring

2. Clarification of requirements

3. Compilation of team / network / stakeholders

4. Structuring, thinning out by reducing unnecessary components, configuration management

5. Specifications and knowledge management, identification

6. Updating and optimization of data (CAD / ERP / PDM)

7. Gradual integration and transfer of results to productive operation

8. Support & optimization

Interim management in engineering

Project management

- Configuration management

- Capacity management

- Process optimization

- Quality management

- Requirements management

- Technical specifications

- Knowledge management

- Modularization

- Standardization

- Project Management

- Supply chain management

- Leadership

- Operational change management

2. Calculable project results

3. Reliable delivery times

4. Robust quality

5. Satisfied customers and growth potential

6. No mirco-management

7. Lean, efficient, flexible and motivated organization

8. Short familiarization times as a door opener for flexibility

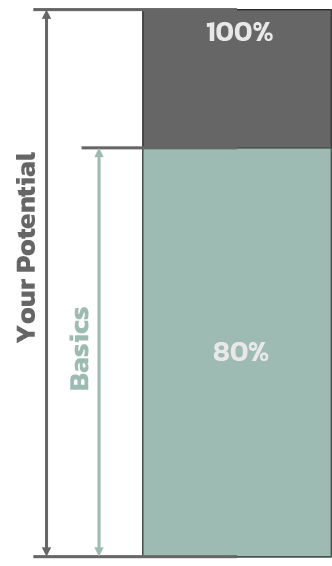

We organize the basics for you!

You benefit in the short term

The problem with stalling projects and processes in mechanical and plant engineering

1. The project is not progressing and is stalling.

2. The CEO has to get involved, which means he has to

neglect his actual strategic function.

3. Deadlines are repeatedly postponed.

4. The organizational size of the project is too large, so the team works inefficiently.

5. Customers need to be informed and are dissatisfied.

6. The costs are getting out of hand.

7. In the end, production quality problems occur.

8. Employees are dissatisfied and the search for a solution stalls.

Our services

Stalled projects and a confusing data environment are common in everyday engineering work. The cause are often unconscious human processes, as described by the economic psychologist and Nobel Prize winner Daniel Kahneman (2002). Our brain works efficiently by using unconscious patterns and automatisms in processes, while conscious reasoning often takes effect too late. This explains the situation with stalled projects in engineering: The emotions and the unconscious dominate, causing the solution-finding process to stall. In our projects, we consciously leave our comfort zone.

Our goal at Reascentec is to live our brand essence by continuously going out of our comfort zone and focusing on the following goals: Providing assistance, streamlining and structuring the technical foundation, ensuring professional competence and success, delivering project metrics, establishing a lean and efficient organization and reducing costs.

Our approach to engineering -

engineering made simple -

leaving the comfort zone,

structuring and streamlining

Our Approach

a. Improving the accessibility to input information

b. Structuring and organizing of unstructured data

c. Creating logical product structures

d. Ensuring comprehensive documentation as the basis for optimization

e. Promoting networking within engineering

f. Ensuring compliance with relevant standards and regulations

the main challenge is often not their mere existence, but their consistent implementation

g. Introduction of company know-how as a manufacturer

h. First streamline, then digitize

i. Eigenverantwortung, Fehlertoleranz und Zuverlässigkeit

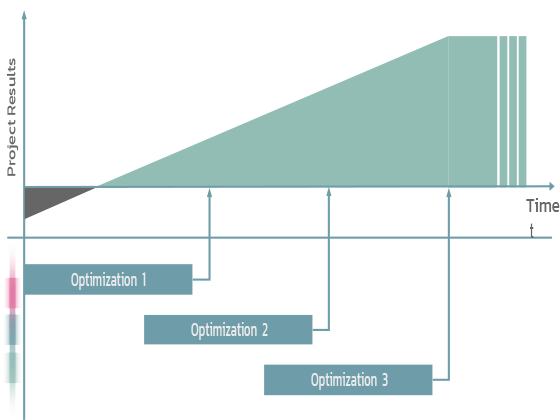

j. Gradual streamlining and structuring

k. Create a database for digitalization and modern technologies

1. Analysis and objectives

2. Clarification of requirements

3. Compilation of team / network / stakeholders

4. Structuring, thinning out by reducing unnecessary components, configuration management

5. Specifications and knowledge management, identification

6. Optimization potential / innovation potential

7. Updating and optimization of data (CAD / ERP / PDM)

8. Gradual integration and transfer of results to productive operation

9. Support & optimization

Our services

- Optimization in engineering

- Interim management in engineering

- Project management

– Technical change management

– Configuration management

– Capacity management

– Process optimization

– Quality management

– Requirements management

– Technical specifications

– Knowledge management

– Modularization

– Standardization

– Project Management

– Supply chain management

– Leadership

– Operational change management

WE FOCUS ON THE IMPORTANT TOPICS

1. 25…50% lower manufacturing costs (TCO)

2. Calculable project results

3. Reliable delivery times

4. Robust quality

5. Satisfied customers and growth potential

6. No mirco-management

7. Lean, efficient, flexible and motivated organization

8. Short familiarization times as a door opener for flexibility

We organize the basics for you!

We optimize step by step

You benefit in the short term

Efficient engineering management in mechanical engineering

Incomplete information and specifications in engineering management

Incomplete information and specifications pose a considerable challenge in the field of engineering management. An engineering manager must ensure that all relevant data and requirements are clear and complete at the start of a project. Missing or unclear specifications often lead to delays, increased costs and unforeseen problems in the course of the project. To avoid this, it is crucial that communication between all departments and stakeholders involved is effective and transparent.

Undetected errors and optimization potential in projects

In engineering plant construction, there is often a risk that errors remain undetected and optimization potential is not exploited. An engineering manager should therefore carry out regular checks and optimizations to ensure that projects run efficiently and error-free. By using modern analysis and monitoring technologies, errors can be detected and rectified at an early stage, resulting in better overall project performance.

Unstructured data and its impact

Unstructured data can significantly impact both the efficiency and the success of industrial engineering and management projects. Without clearly structured data, it becomes difficult to find and use important information quickly and accurately. This leads to delays and increased effort in data processing. A structured approach to data management helps to minimize these problems and improve decision-making.

Disregard for internal standards and resulting consequences

Neglecting internal standards can have serious consequences for a company. Internal standards are essential to ensure consistently high quality and efficiency. Engineering managers must therefore ensure that all employees understand and comply with the defined standards. Regularly reviewing and updating these standards is also necessary to keep up with changing requirements and technologies.

Avoiding technically unrealizable solutions

In the field of engineering management, it is important to avoid technically unrealizable solutions. This can be achieved through a thorough feasibility study and close collaboration with technical experts. Engineering managers should ensure that all proposed solutions are both technically feasible and economically viable. This in turn helps to avoid costly mistakes or failed projects.

Challenges due to uncertain lead times

Unsecured lead times are a major challenge in engineering plant construction. Unforeseen delays can lead to significant cost increases and project delays. An engineering manager should therefore take measures to maintain lead times and plan for sufficient buffer times. This also includes close monitoring of project progress and the timely identification and elimination of bottlenecks.

Minimizing potential error sources in production

Minimizing error sources in production is a central aspect of industrial engineering and management. Errors in manufacturing can lead to significant quality problems and rework. An engineering manager should therefore continuously look for ways to identify and eliminate error sources. This can be achieved through the implementation of quality control systems and regular employee training.

Solving issues with input information and processes

Problems with input information and processes can significantly affect the efficiency and quality of projects. An engineering manager should make sure that all input information is both complete and accurate and that processes are clearly defined and designed efficiently. This can be achieved by introducing standardized checklists and processes to ensure that no important information is overlooked.

Why Reascentec?

Reascentec offers custom engineering management solutions to overcome these challenges. With our expertise, we help companies to improve the accessibility of input information and create a structured data environment. Our services aim to increase efficiency through logical product structures and ensure comprehensive documentation.

Improving the accesibility to input information

Reascentec supports companies in increasing the accessibility to input information. By employing modern IT solutions and data management systems, we ensure that all relevant information is accessible quickly and easily. This not only reduces the time spent searching for information, but also increases the efficiency and accuracy of project management.

Structured data for better results

Structured data is crucial for the success of industrial engineering and management projects. Reascentec helps companies structure and efficiently manage their data. This leads to better results and a higher quality of project execution. By implementing data management systems and processes, we help our clients to use their data effectively.

Increased efficiency through logical product structures

Logical product structures are a key factor for efficiency in engineering plant construction. Reascentec helps companies optimize and standardize their product structures. This leads to a clearer overview and simpler management of products and processes. Our experts work closely with customers to develop customized solutions that meet their specific requirements.

Ensuring comprehensive documentation

Comprehensive documentation is essential for the success of any project. Reascentec helps companies ensure complete and accurate documentation. This includes the creation and maintenance of technical documentation, specifications and process descriptions. Good documentation helps avoid misunderstandings and ensure the quality and consistency of work.

Networking in engineering

In the engineering sector, networking is an essential aspect of exchanging knowledge and experience in order to benefit from best practices. Reascentec promotes exchange and collaboration between different companies and professionals in the field of engineering management. Through regular events and workshops, we provide a platform for the exchange of ideas and the development of innovative solutions.

Success Stories and Case Studies

Our success stories and case studies show how Reascentec has helped companies overcome their engineering management challenges. Through customized solutions and close collaboration with our clients, we have successfully completed numerous projects and achieved sustainable improvements. Visit our website to find out more about our case studies and success stories.

Contact us for a solution tailored to your needs

To learn more about how Reascentec can help your company with engineering management, please contact us. We offer customized solutions tailored to your specific needs. Our team of experts is available to answer your questions and help you successfully implement your projects.