Experience in

Engineering

management

reascentec – Stephan Harms

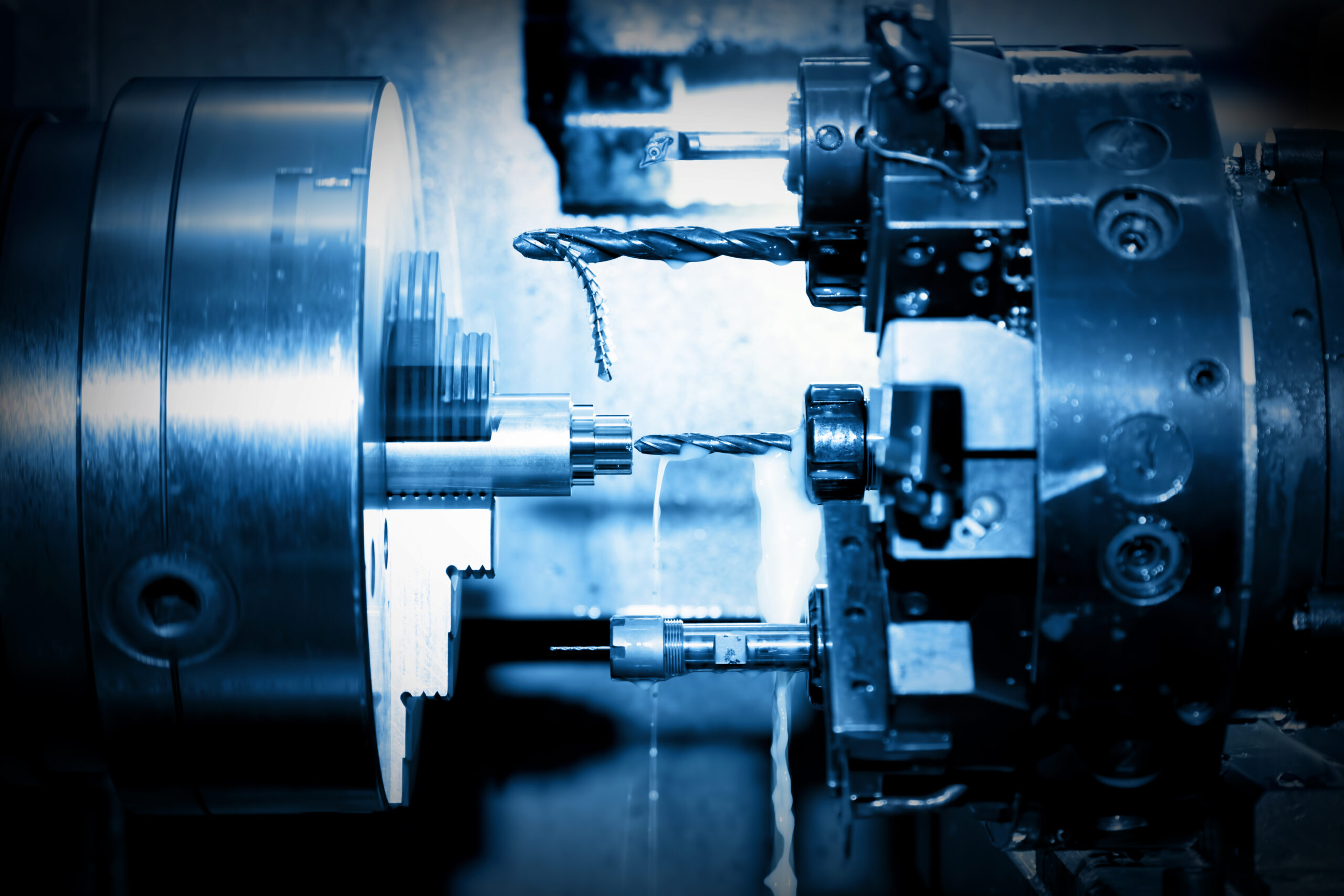

Machines have always been a part of my life. I remember my first machine. I was 5 ½ years old. I had oil under my fingernails for 20 years and got to know all facets of it. A very valuable experience. It’s a very rewarding feeling when everything works in the end. A relatively brief moment that makes all the effort worthwhile. This practical relevance, or the basic understanding of how things are created or function, is still incredibly important to me today.

In production, you have to live with what is on the plans. The design options are (rightly) very limited. That was the reason why I decided to study mechanical engineering. I want to design. This was followed by various positions as a design engineer, project manager, design and technical manager in Germany and abroad. I particularly enjoy the business of international projects. If there is a one common language, it is technology.

Engineering has the greatest influence on the overall process in mechanical and plant engineering. My experience: If the engineering is right, then the project results are also right. The prerequisite is, of course, that all requirements and interests are recorded and taken into account right from the start. Engineering is much more than just a drawing. The company’s internal relationships and structure from supply to delivery are also crucial in this regard. Processes must be simple and practicable. Everyone involved in the process must perceive added value in the medium term. I am a big fan of LEGO.

In practice, the picture is often different. The opportunities for internal managers to initiate the necessary changes are very limited – they simply disturb the harmony within the company or disturb established processes. As a direct consequence, the project results fall well short of what is possible. Further development stagnates at various levels and reasons are always found as to why something is not working. Day-to-day business is increasingly dominated by problem solving. But shouldn’t we actually be concerned with preventing problems?

Another bitter realization: The fun is quickly lost. Many employees take refuge in acceptance or reorient themselves. General uncertainty is increasing. Just don’t make any mistakes – don’t be at fault. You stand in your own way. We have to leave this false comfort zone. Because it doesn’t benefit us on a rational or emotional level. Looking back, I realize that all development projects have worked so far. Perhaps not always perfectly, but it has always been worthwhile. It’s particularly exciting to see what ideas you come across along the way. Nothing is as certain as development.

I will never forget the feeling I had as a prospective engineer when the first component was delivered according to my own drawing and ideas. That was simply overwhelming. This opportunity to apply your own knowledge and realize your own ideas is a gift. Unfortunately, it is accepted far too little.

Today, I help businesses and, above all, their employees to leave their comfort zone. It gives me great pleasure to see when changes are accepted and implemented independently. Employees are actively working on solutions and are motivated to do so, taking on responsibility and trying out new things – which ultimately works out. So much more is possible – we just have to do it and make engineering what it actually is.

reascentec will continue to expand its expertise. As a reliable partner for structuring in engineering, management of special and large-scale projects, as well as reconstruction of companies in mechanical and plant engineering. From one single source, with a well-coordinated team and straightforward implementation – because anyone can do complicated.

Competencies

– Change management

– Configuration management

– Capacity management

– Process optimization

– Quality management

– Requirements management

– Technical specifications

– Knowledge management

– Modularization

– Standardization

– Project management

– Supply Chain Management

– Leadership