in mechanical engineering

Clean up and structure -

in small steps

Product development in mechanical engineering Approaches and strategies

a. Improving accessibility to input information:

achieve our goals of “Providing assistance” and strengthening “Professional competence and success”, it is crucial to involve the team and make existing knowledge accessible. Every employee should take responsibility to promote further development and leave our comfort zone

b. Unstructured data:

As part of our “Streamlining and structuring the technical foundation” work, a thorough clean-up and structuring of the existing unstructured data is required. Currently, the accuracy, completeness or timeliness of the data is unknown. Our aim is to carry out comprehensive streamlining and ensure a clear data structure

c. Logically organized product structures:

We rely on logical product structures to fulfill the strengths of “Professional competence and success” and “Lean and efficient organization”. These not only reduce the workload and the number of variants, but also minimize lead times. This leads to considerable organizational advantages, as designers can focus on individual assemblies or functional modules, which increases flexibility in the change management and reduces lead times.

d. Ensuring comprehensive documentation:

To support our values of “Providing assistance” and “Delivering project metrics”, it is important to establish clear documentation guidelines and manage them centrally. Once established, documentation provides an excellent basis for continuous improvement and supports collaboration with external resources or new employees.

e. Networking in engineering:

To strengthen our goal of “Professional competence and success”, collaboration with other disciplines is essential. Designers should actively engage with other disciplines by participating in interdisciplinary discussions and meetings.

f. Compliance with standards and regulations:

In line with our values “Streamlining and structuring the technical foundation” and “Lean and efficient organization”, the main problem is often not the mere existence of standards and norms, but ensuring their consistent implementation.

Process optimization

g. Contribution of company know-how as a manufacturer:

In order to realize the value of “Professional competence and success”, it is crucial to use the company’s own know-how to develop optimal solutions and increase efficiency.

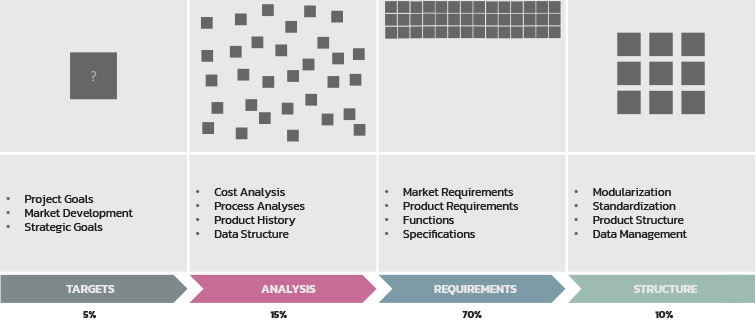

h. First streamline, then digitize Our clear

recommendation is to first streamline and optimize the way you work before moving to digitization. This corresponds to our goals of “Streamlining and structuring the technical foundation” and “Lean and efficient organization”. It is advisable to involve a partner at an early stage in order to support the process efficiently and achieve our goals

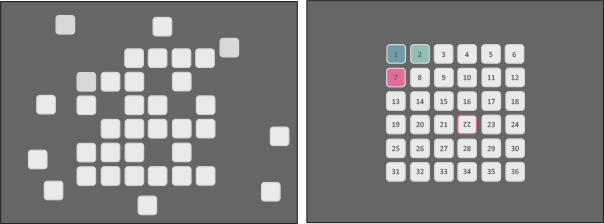

i. Gradual streamlining:

Thorough streamlining should be the first step. This is followed by the optimization phase, in which the results of the previous phase are applied. This creates a clear overview and supports the values of “Delivering project metrics” and “Reducing costs”.

j. Importance of engineering in mechanical and plant engineering:

Engineering is at the heart of mechanical and plant engineering. A change in engineering inevitably leads to changes in the entire process. Well thought-out and structured technical solutions lead to positive project results and manageable technical challenges, which corresponds to our “Professional competence and success” service.

reascentec - Methode

Improve accessibility to input information

Promote knowledge transfer within the team

Product development in mechanical engineering is heavily dependent on knowledge transfer within the team. Very often, valuable know-how is only stored in the heads of the employees. In order to optimize product development in mechanical engineering, it is crucial to promote knowledge transfer and thus improve accessibility to input information. This ensures that all team members have access to the same knowledge and can therefore be more productive.

Structuring unstructured data

Unstructured data is a common problem in technical product development. A thorough structuring of this data is essential in order to increase the efficiency of product development. By structuring unstructured data, errors can be avoided and the entire development process can be accelerated.

Logically organized product structures for increased efficiency

Reduction of variants and lead times

Logically organized product structures are a key factor in increasing efficiency in product development in mechanical engineering. By reducing variants and lead times, resources can be used more efficiently and costs can be reduced. A well thought-out product structure enables engineers to concentrate on essential assemblies, which supports product optimization through various approaches in mechanical engineering.

Organizational advantages through product structuring

The structural organization of products offers significant advantages. A clear product structure helps to simplify processes and optimize product development in mechanical engineering. This leads to better plant optimization and contributes to the successful implementation of projects.

Ensuring comprehensive documentation for optimization

Define guidelines for effective documentation

Comprehensive documentation is essential for the continuous improvement and optimization of products. It is important to establish clear guidelines for documentation to ensure that all relevant information is captured and accessible. This supports technical product development and ensures high quality of developed products.

Using documentation for continuous improvement

The use of well-structured documentation allows for the implementation of continuous improvements in product development. By regularly reviewing and updating the documentation, weak points can be identified and rectified, leading to continuous optimization of the products.

Networking in engineering for interdisciplinary solutions

In engineering, networking plays a crucial role in the development of interdisciplinary solutions. The exchange with other departments promotes innovative ideas and contributes to product optimization through different approaches in mechanical engineering. Through interdisciplinary cooperation, complex problems can be solved more efficiently and the overal quality of products can be improved.

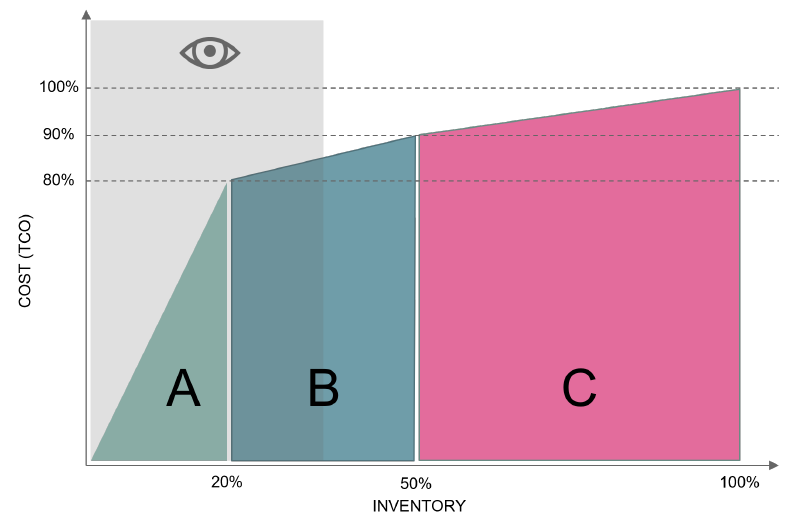

reduce costs

Early defect detection and quality improvement

Early defect detection is important for quality improvement in mechanical engineering product development. Regular tests and inspections allow potential problems to be identified and rectified at an early stage. This improves product quality and reduces the cost of rework.

Implementation and adaptation of designs

Implementation and adaptation of designs are key steps in product development in mechanical engineering. Flexible adaptation of designs makes it possible to react quickly to changes and requirements. This contributes to increased efficiency and plant optimization.

Test based validation for mass production

Validation through testing is another critical step in ensuring that the developed products are suitable for mass production. The functionality and reliability of the products can be checked and guaranteed through extensive testing.

Process optimization from the very beginning

Early process optimization is indispensable for maximizing the efficiency of product development in mechanical engineering. By systematically planning and optimizing processes, resources can be better utilized and product development can be accelerated.

Compliance with standards and regulations

Compliance with standards and regulations is crucial for the quality and safety of the products we develop. The consistent implementation of these specifications ensures that the products meet the required quality standards and function reliably.

Incorporating the know-how as a manufacturer

In-house know-how is a valuable advantage in product development in mechanical engineering. By incorporating this knowledge, it is possible to develop more innovative solutions and increase efficiency. This leads to successful product optimization and a lean, efficient organization.

Overall, product development in mechanical engineering is a complex process that requires continuous optimization and adaptation. By implementing the above strategies and approaches, companies can increase their efficiency, reduce costs and improve the quality of their products.

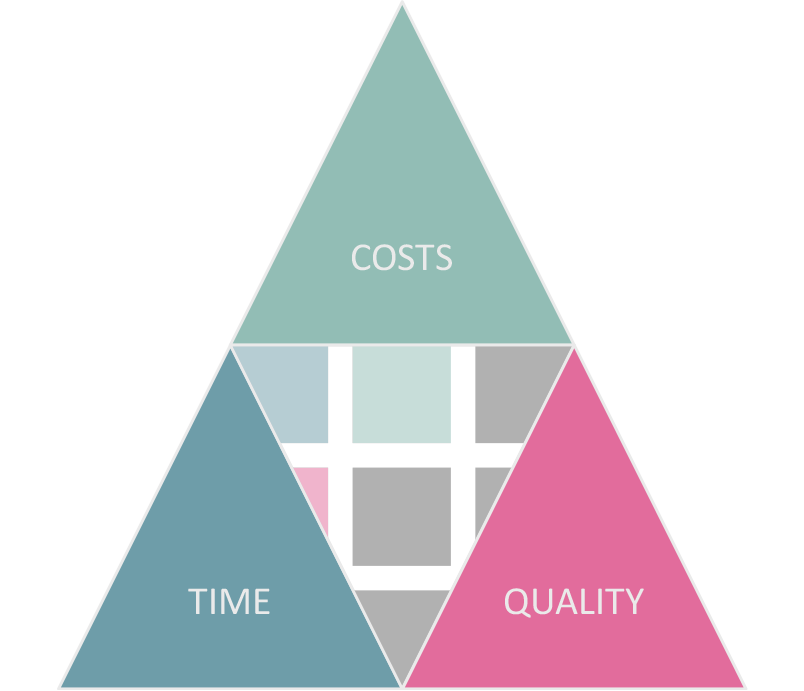

Project variables